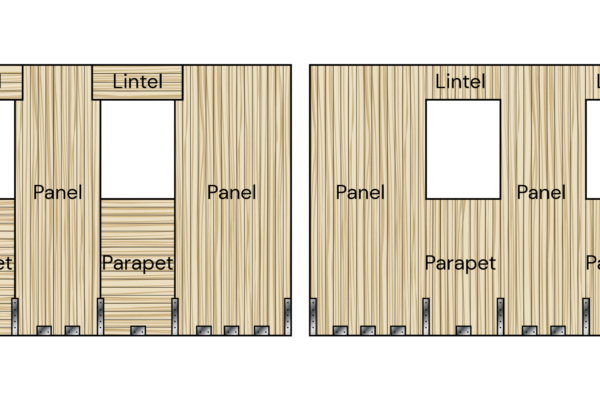

In Mass Timber buildings, glued laminated timber (GLT), also known as glulam, is a versatile and high-strength material that offers flexibility for architects and engineers. Notches in beams can occur because of architectural, structural, or other requirements in mass timber projects. Sometimes, notches can be too big (high) for remaining part of beam member to transfer loads to the support, so additional reinforcement is needed. Understanding how to reinforce GLT notches is crucial for ensuring structural safety and durability. In this blog, we will explore the design principles, reinforcement techniques, and practical considerations for reinforced GLT notches.

What is a GLT Notch?

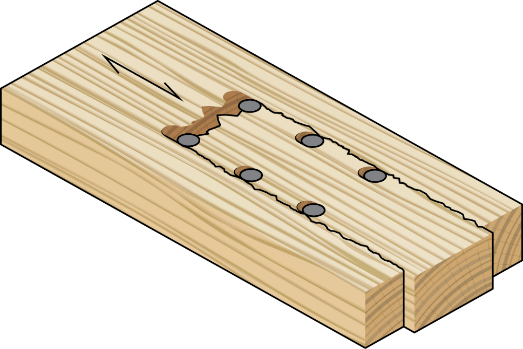

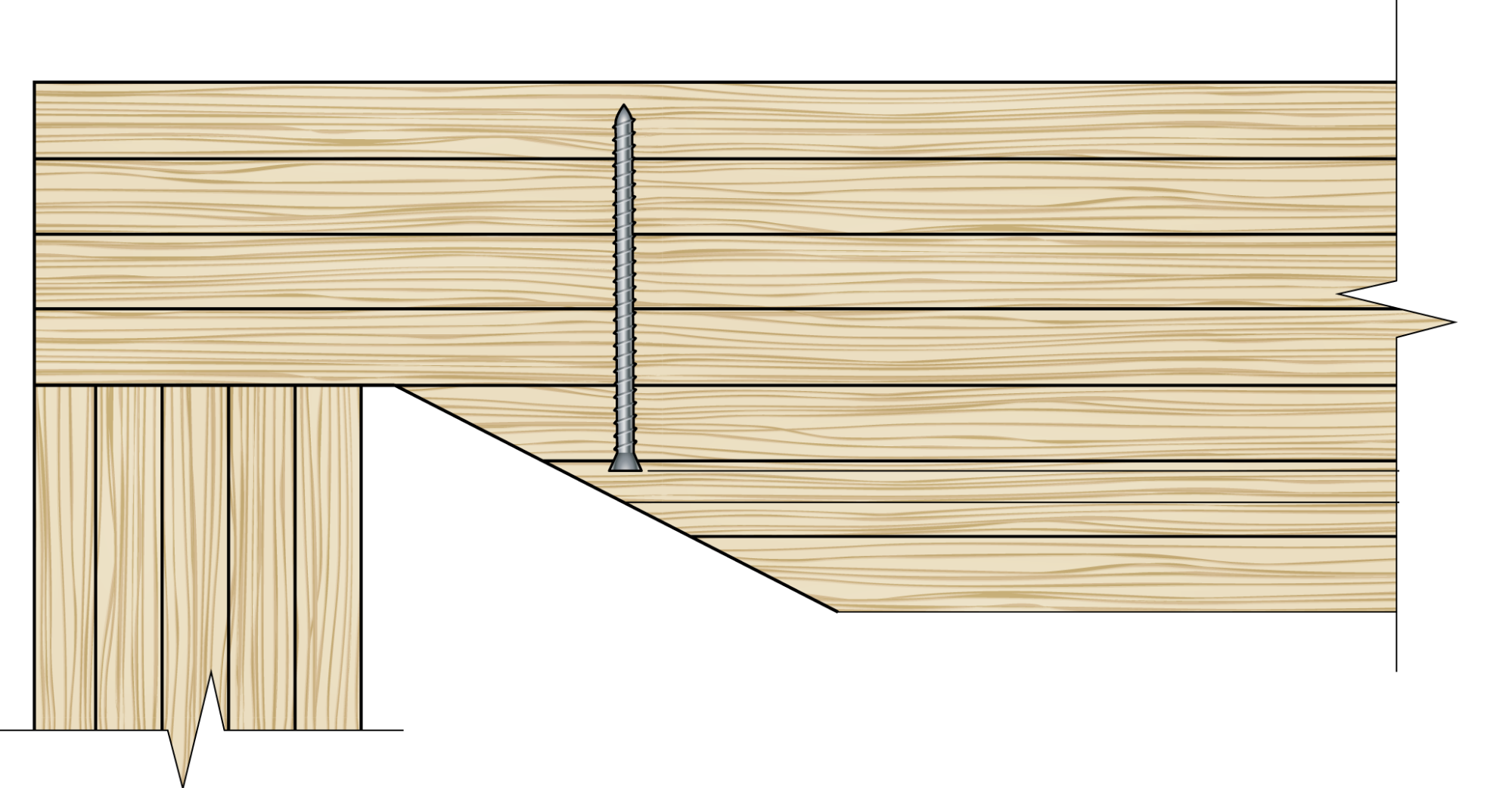

A notch in a GLT beam refers to a localized cut or reduction in the cross-sectional area of the beam, typically at the points where beams are supported by another beam or column. Notches are often necessary for functional or architectural reasons, but they can reduce the strength and stiffness of the member, particularly under bending and shear forces. This is why reinforcing these notches is essential for maintaining the integrity of the structure.

Why Reinforce a GLT Notch?

When a notch is introduced in a GLT beam, the stress concentration in that area increases significantly. This makes the beam more susceptible to shear failures, cracking, or even catastrophic failure under load. Reinforcing the notch significantly increases the beam’s load-bearing capacity to carry shear and bending stresses, therefore reducing localized failures.

Reinforcement becomes especially important when:

- Notches are deep or positioned in areas of high bending moment.

- Heavy point loads or long spans are present.

- Notches located near support.

Design Considerations for Reinforced GLT Notch

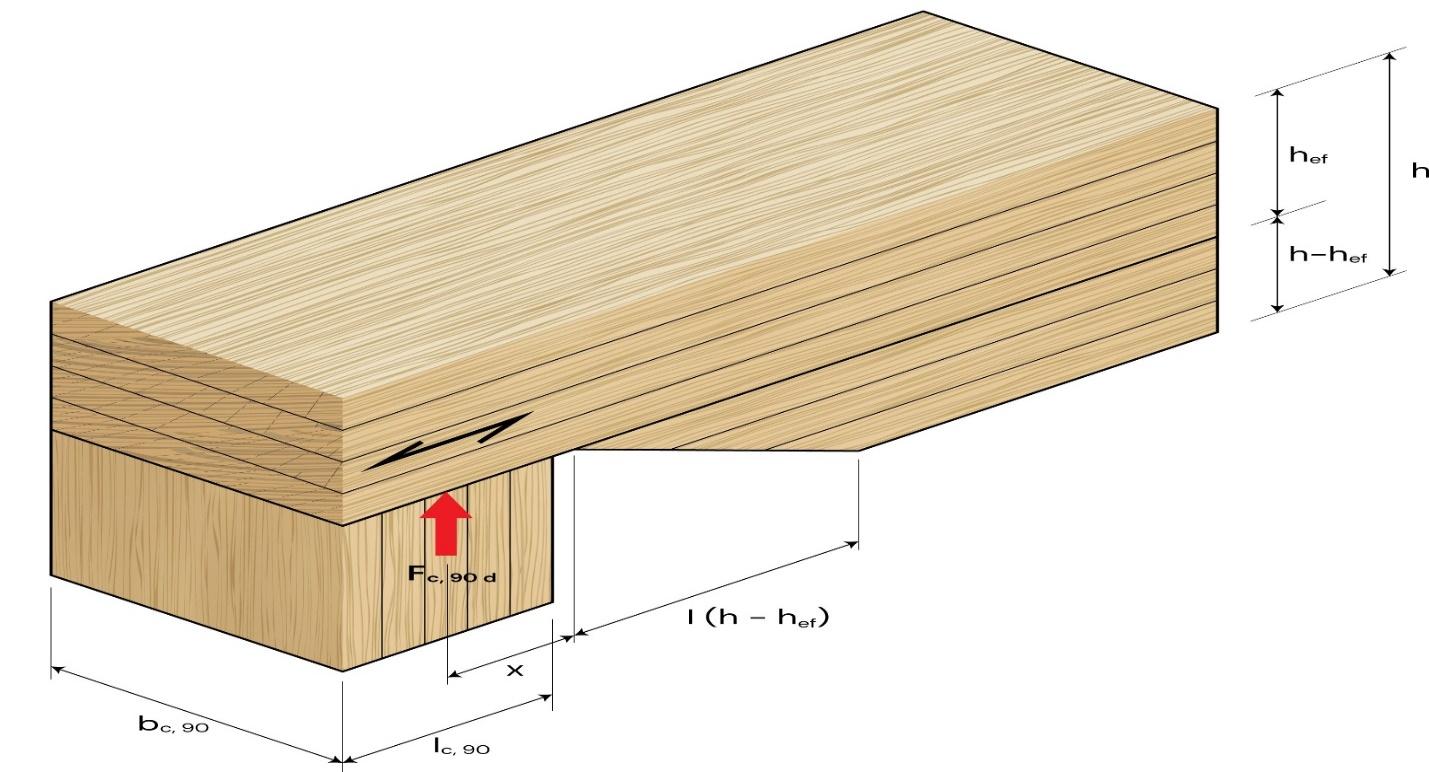

- Notch Depth: Deeper notches significantly reduce the effective cross-sectional area of the beam, reducing the beam’s load-bearing capacity. As a general rule, the depth of the notch should be minimized where possible, and the remaining depth of the beam above the notch should be sufficient to carry the bending and shear force.

- Notch Location: Notches located near supports (end notches) are more prone to failure due to high localized shear stress.

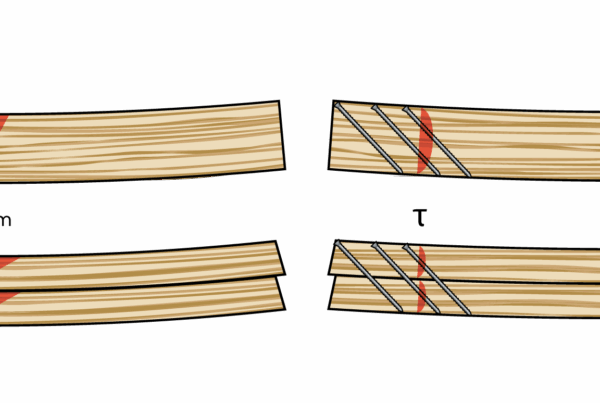

- Notch Shape: Sharp corners at the notch, such as vertical notches, lead to stress concentrations. Inclined notches are preferred to reduce stress concentrations.

- Shear Stress Management: Reinforcing the notch reduces the effect of stress concentration by re-distributing the stresses around the notch, reducing localized stress concentration and enhancing the beam’s capacity to resist shear forces.

- Tension Perpendicular to Grain: Timber is particularly vulnerable to tension perpendicular to the grain, which can occur near notches. Reinforcement should be designed to reduce or redistribute these tension forces and prevent brittle failures where necessary.

- Material Compatibility: Self-Tapping Screws or rods are reinforced to resist tension perpendicular to grain and enhance shear strength.

- Connection Design: Adequate attention must be given to how the reinforcement connects to the GLT beam, ensuring that load transfer between the beam and reinforcement is efficient and without localized overstress.

Reinforcement Techniques for GLT Notches

Self-tapping Screws or rods: Fasteners such as fully threaded screws or rods are used as a reinforcement to reduce splitting or cracking at the notch and transfer loads between the notched beam and the supporting member. They are particularly effective in reducing tension perpendicular to the grain and localized shear stress.

How CLT Toolbox Simplifies Timber Connection Design of Reinforced GLT Notches

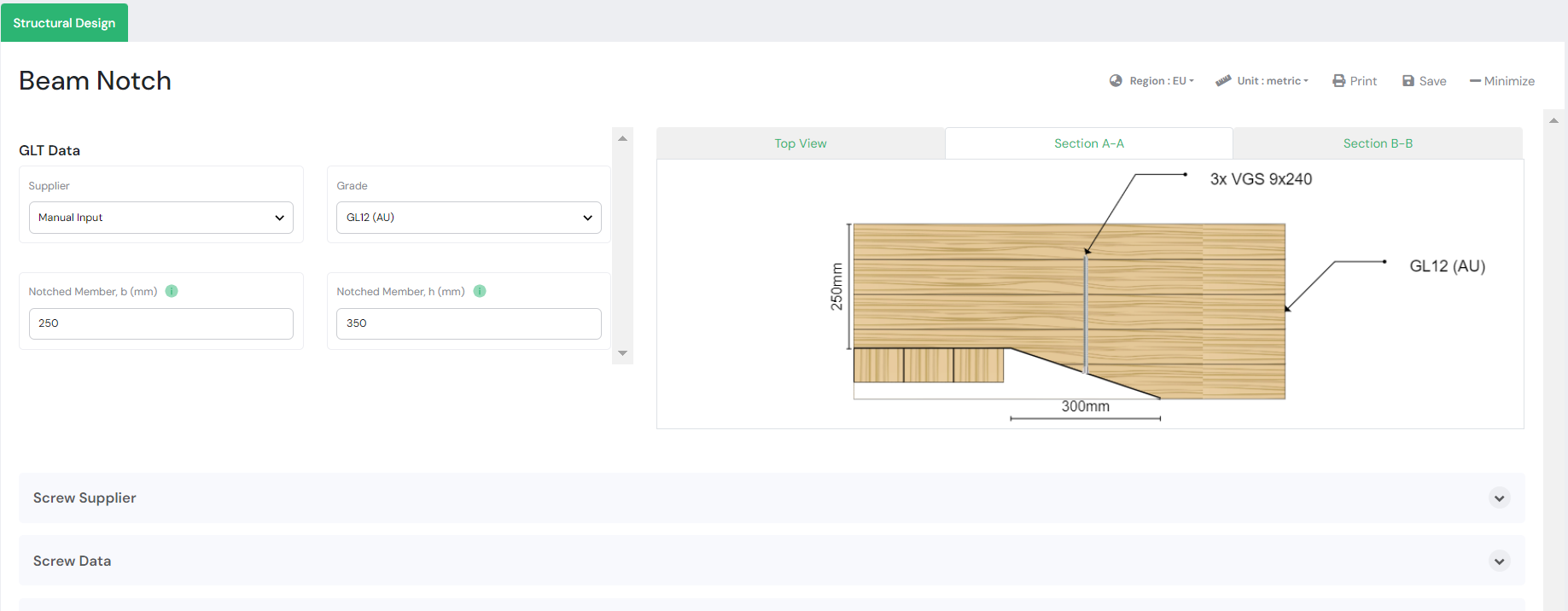

CLT Toolbox offers a suite of tools and resources designed to address timber connection challenges in the design of Reinforced GLT Notches with advanced analysis capabilities. The user interface is simple to use, which features a dynamic graphic that allows you to observe how the inputs change accordingly.

1. Input Section: The input section allows you to insert user desired inputs for notched GLT beams such as, choosing the GLT material type among various suppliers, dimension properties, choosing reinforcement screws from our database along with manual input option, selecting design codes, and also inserting the magnitude of design shear force, which is the design load for this calculator.

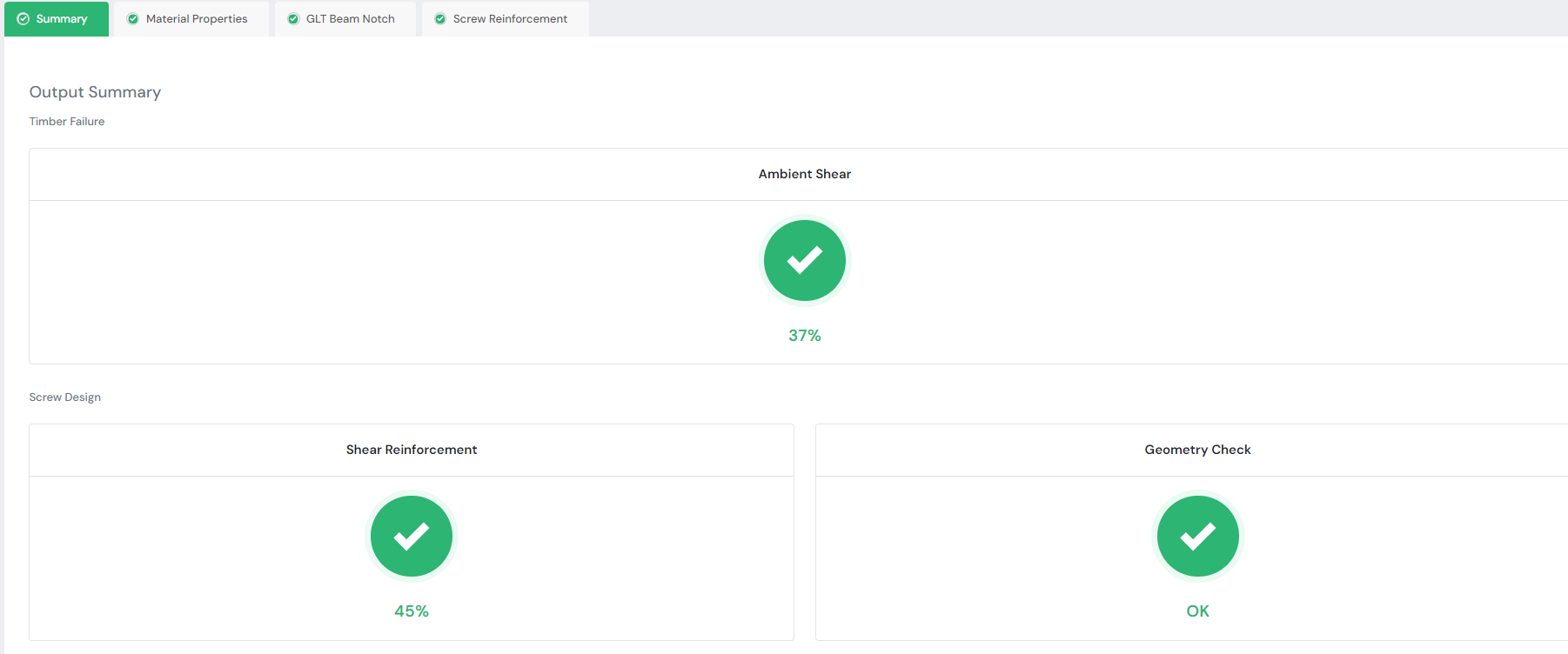

2. Output Summary: The output summary displays the major checks for this calculator which are the Shear checks with and without reinforcement and the geometry check of the notched GLT beam respective to the applied design load.

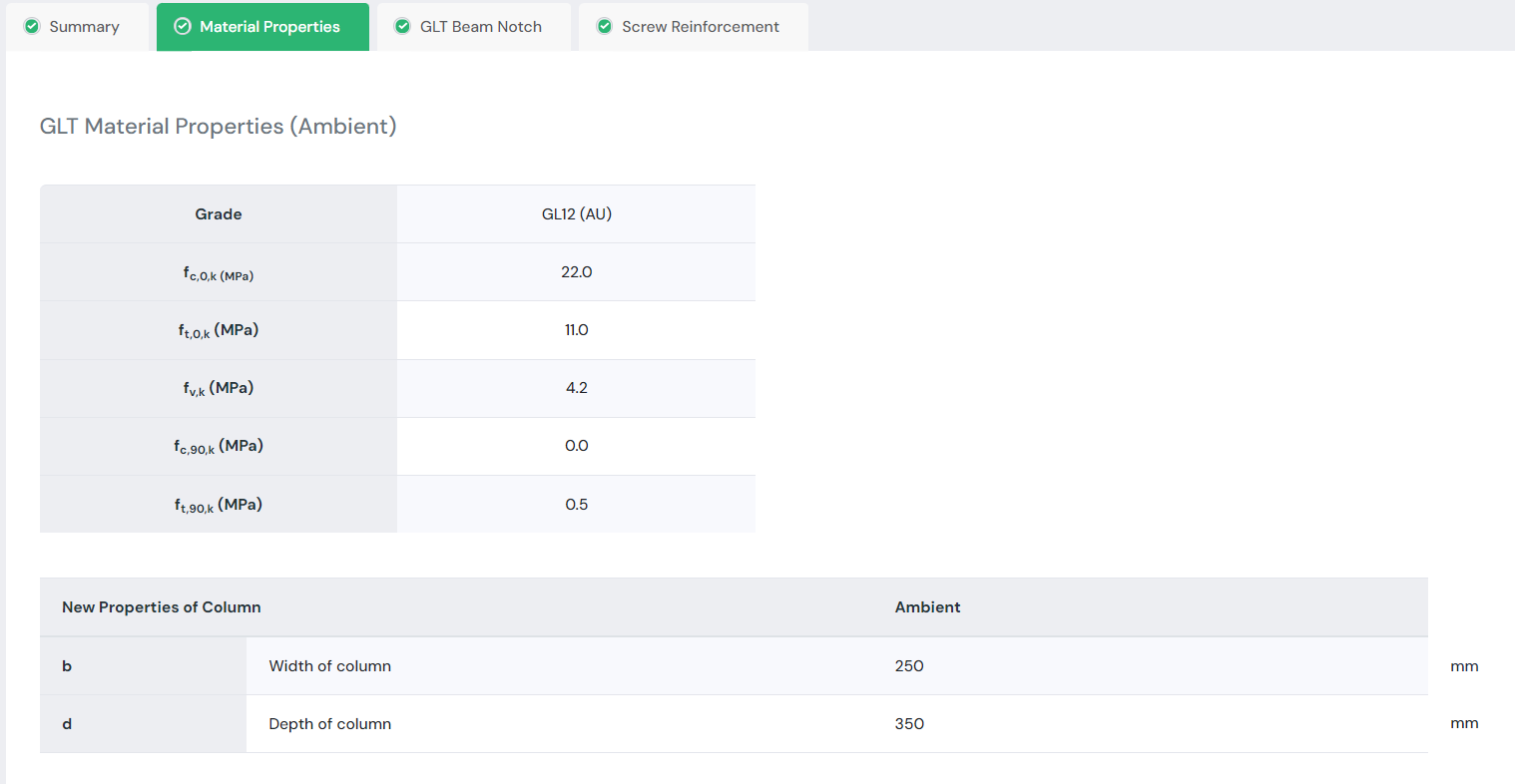

3. Material Properties: The material property tab shows the respective material properties of the selected GLT material.

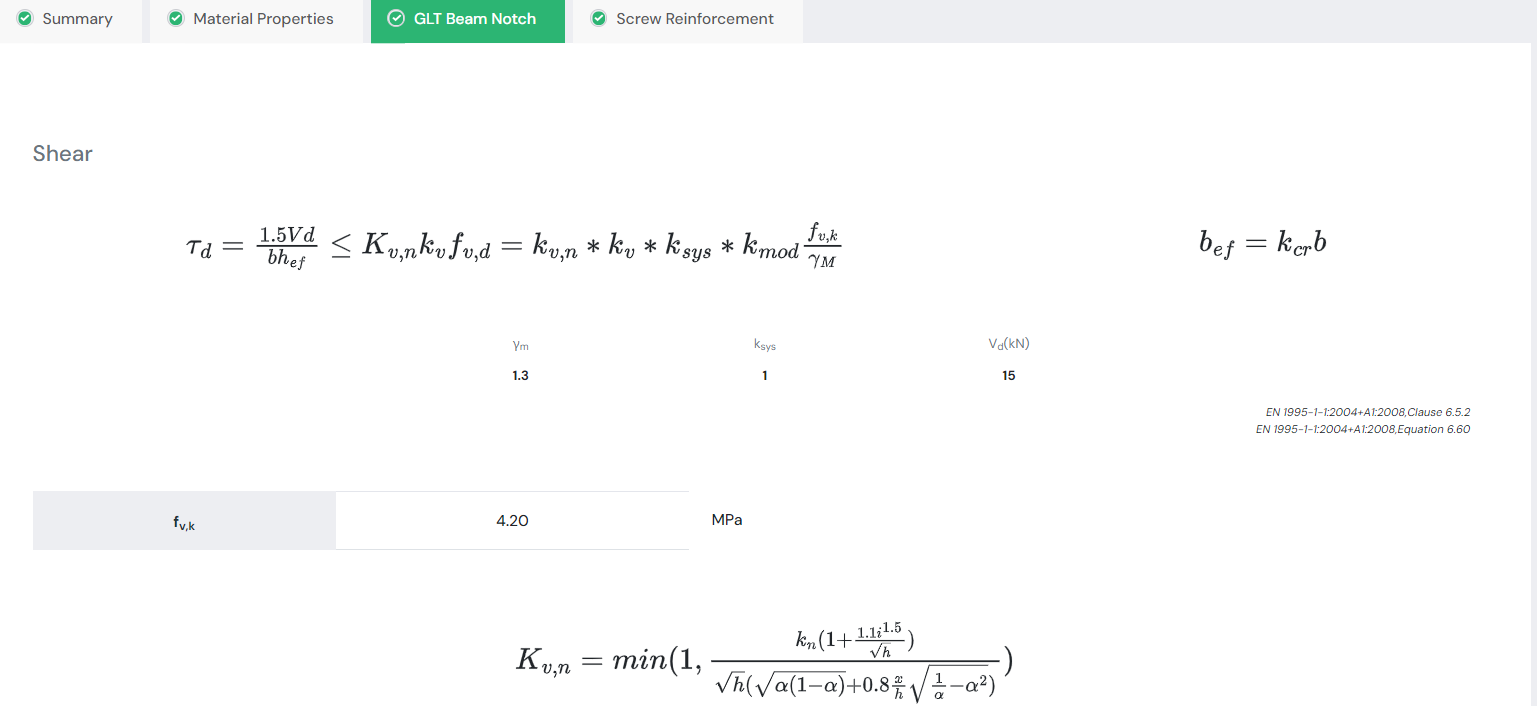

4. Shear Check: The shear check of the notched section without reinforcement is checked under this specific tab. This tab performs the actual calculation for such type of timber connections. The calculations are performed in a brief manner, avoiding any possible black boxes, and are carefully referenced to their corresponding design codes, making them easily understandable, and educational. This check is conducted using the current European code EN 1995:2004, the new draft code EN 1995:2023, and the Australian Standards AS 1720:2010.

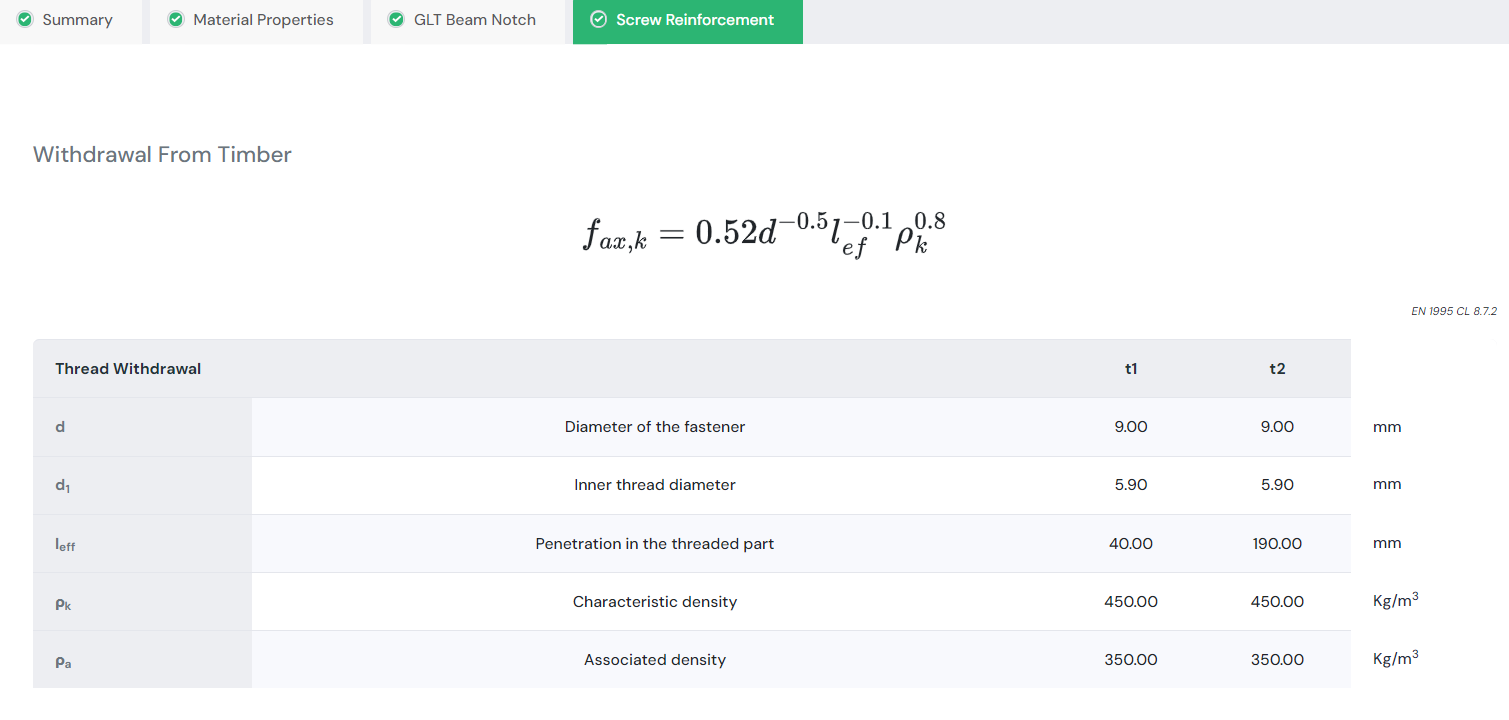

5. Screw Reinforcement: This section comprises the geometry check of the notched section and the shear capacity due to the screw reinforcement. Reinforcement according to design codes and ETAs are used for this check.

Best Practices for Reinforced GLT Notch Design

- Minimize Notch Depth: When possible, avoid deep notches in GLT beams, as they substantially reduce the effective section, affecting both shear and bending capacity of the beam. Limit the depth of the notch to reduce stress concentrations.

- Adequate Spacing and Fastner Sizing: For fasteners (screws, or rods), maintain adequate spacing to avoid splitting the wood and ensure proper load transfer across the notch. Follow the minimum spacing and edge distances prescribed by timber design codes to prevent stress concentrations and localized failures.

- Follow Standards and Guidelines: Reinforcing GLT notches should be done in compliance with relevant design codes such as Eurocode 5, Australian Standard, and in accordance to ETA (European Technical Assessment), or NDS (National Design Specification). Our software CLT Toolbox, uses the current European code EN 1995:2004, the new draft code EN 1995:2023, the Australian Standards AS 1720:2010, and various ETAs.

Conclusion

Reinforcement of notches in GLT beams is an essential design consideration when notches are located near supports, under high loads, or when the notch depth significantly reduces the beam’s effective cross-section capacity. By following proper reinforcement techniques and design guidelines, engineers can ensure that notches in GLT members do not become a weak point in the structure, sustaining the beam’s capacity to withstand shear and bending forces. At CLT Toolbox, we provide specialized tools and calculators that simplify the design and analysis of reinforced GLT notches. Our platform helps engineers ensure compliance with industry standards and delivers accurate results, saving time and improving design efficiency.