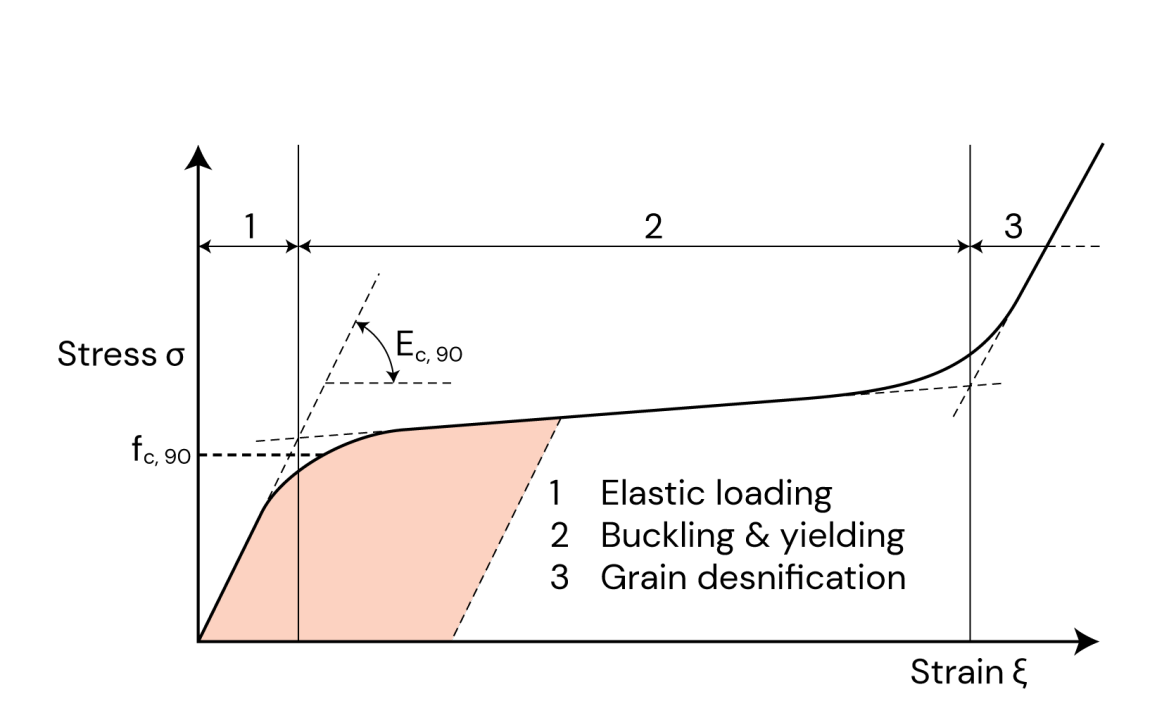

Timber is a natural, “living” material, which means it comes with inherent variability in its physical and mechanical properties. One of the most important characteristics engineers must account for is its orthotropic behaviour — timber’s strength and stiffness change depending on the direction of the load relative to the grain. When loaded parallel to the grain, each fibre behaves like a small hollow column, supported by its neighbours. But when timber is compressed perpendicular to the grain, the cell walls collapse under pressure, offering far less resistance. This makes it significantly weaker and more prone to deformation in that direction.

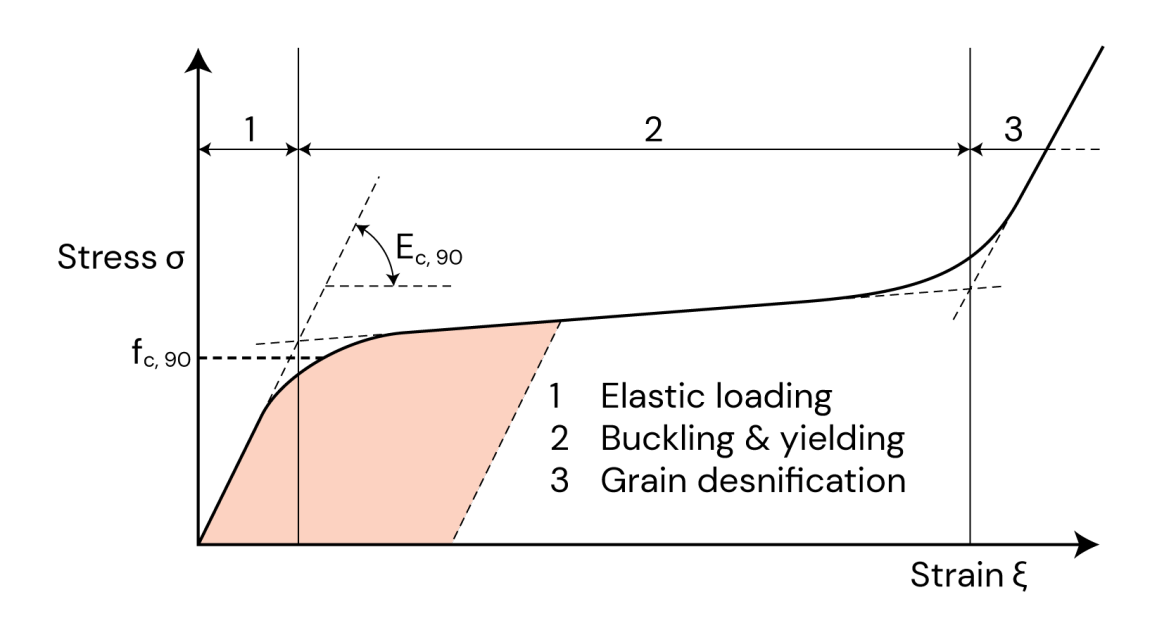

Compression strength perpendicular to grain is a critical consideration when designing timber connections. All major timber design codes provide values for this property across various timber grades, but these values can vary significantly between codes. This variation stems from the complex nature of the property itself — it’s not purely elastic, but elasto-plastic with strengthening. In practical terms, the strength increases as the contact area between the loaded and supporting surfaces grows under load.

Because of this, it’s essential to understand the deformation level at which the given strength values were determined.

Stress-strain curve of timber compressed perpendicular to grain

Variations in Testing Methods: Block vs. Rail Test

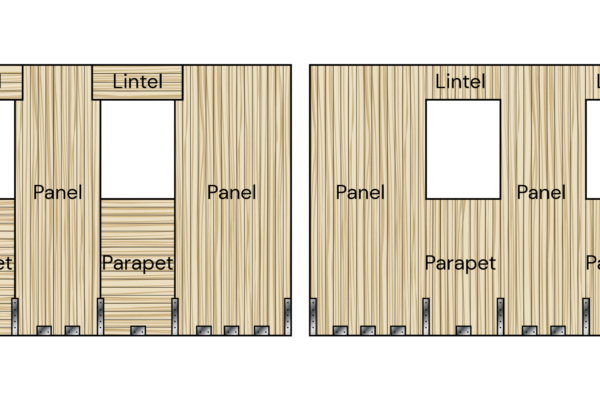

The differences in strength values across design codes stem largely from the distinct testing methods used to determine them. In today’s session, we’ll look at how these values are defined and applied in NZS AS 1720 compared to the Eurocode. For instance, NZS AS 1720 specifies a bearing strength (f’p) rather than a true compression strength perpendicular to grain (fc,90). While the two are related, bearing strength refers to the resistance when one element presses into another — capturing the localized effects at the contact interface. This distinction reflects the underlying differences in test procedures and how each code interprets the same failure mechanism.

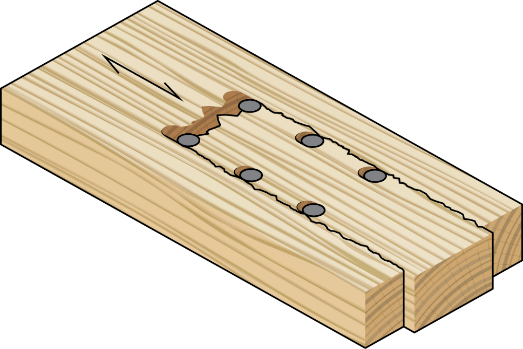

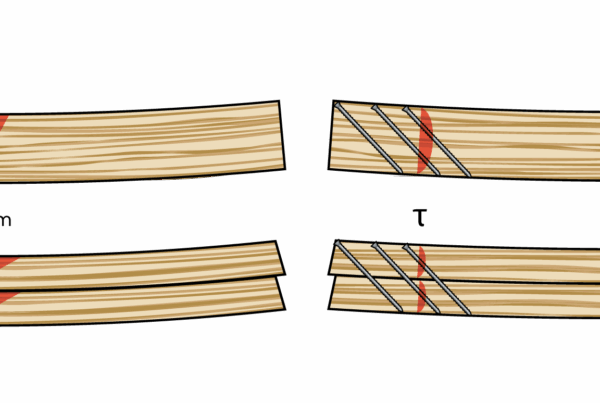

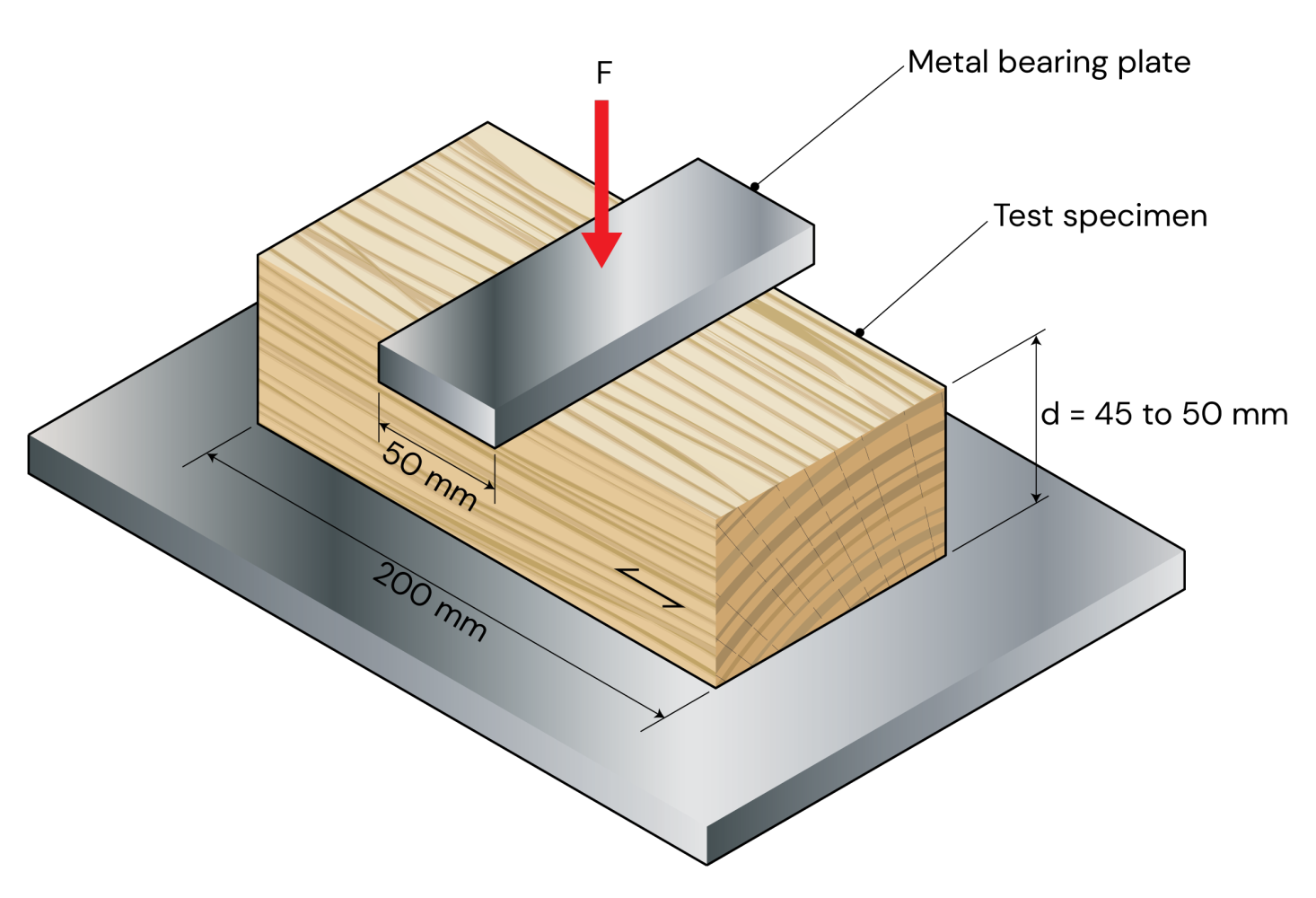

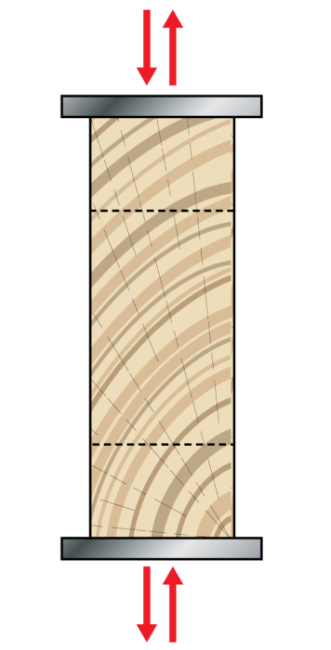

The different methods used to test the compressive strength perpendicular to grain are the “block” test and the “rail” test.

Rail test accordings to AS/NZS4063

Block test according to EN 408

NZS AS 1720.1 Approach (Bearing Strength f’p)

In NZS AS 1720.1, the bearing strength (f’p) is derived from rail testing, which means it captures the effects of the timber both around and beneath the loaded area. This makes it a practical value that includes the interaction between the loaded and supporting members.

This bearing strength is then modified by the k₇ factor and used in Clause 3.2.6 of the standard. The corresponding deformation assumed in this method is about 2 mm into a 40 mm deep member, which equates to 5% of its depth. This makes the value appropriate for Ultimate Limit State (ULS) design in typical applications where some deformation is acceptable.

Eurocode 5 Approach (Compression Strength fc,90,d)

In contrast, Eurocode 5 defines the verification of compression perpendicular to grain using the design compressive strength, denoted fc,90,d. This value is derived from the characteristic strength fc,90,k, which comes from block testing (EN 408) and represents the stress corresponding to 1% non-recoverable nominal compressive strain.

The design strength fc,90,d is calculated by applying material partial safety factors and load duration factors to fc,90,k.

To adapt the pure block test result into more realistic bearing conditions (like those seen in rail tests), Eurocode introduces two adjustments:

- kc,90 factor: Accounts for stress distribution, risk of splitting, and deformation extent.

- Effective bearing length (lₑf): Used in some situations to consider the additional support area provided by timber overhang beyond the actual contact length l.

Comparing Strength Values in Different Codes

Now that we know the differences in testing, let’s compare the values presented in each design code. The NZS 3603 provides a value for a bearing strength perpendicular to grain f’p for SG8 Radiata Pine as 6.9 MPa, while the EN 338 provides a characteristic compression perpendicular to grain strength for C16 softwood as 2.2 MPa.

As it is evident, the values vary by a significant margin. Engineers, who don’t have extensive knowledge of both codes, should keep in mind how these values are derived if they are, for example, designing a mass timber building in New Zealand built from European grades or vice versa in order to provide a safe design.

For more information about this topic please refer to:

- Timber Unlimited Technical Note December 2023: Bearing perpendicular to the grain and NZS AS 1720.1:2022

- Timber Development Association (2019). Characteristic Perpendicular to Grain Bearing Test on Common Australian and Imported Timber Species. Project number: PNA462-1718. Forest & Wood Products Australia.

- Franke and Quenneville (2010). The Material Behaviour of Radiata Pine under Compression. New Zealand Timber Design Journal, Vol 18, Issue 3.