Over the last few years, the CLT Toolbox team has conducted hundreds of demos with structural engineers, and engaged in countless meetings with suppliers across the globe. Throughout this journey, we’ve learned that while some challenges in mass timber are universal, others are uniquely regional.

Now, as we launch our beta in the USA and Canada, we’re excited to introduce ourselves by openly discussing the key problems we’re here to help solve.

Although we’ve already begun conversations with many of the region’s leading engineering companies, suppliers, and industry associations, our early phase as a business is very much focused on learning. Our next step is in the USA/Canada where over the next six months, our primary goal is to listen, adapt, and fine-tune our tooling to ensure it aligns precisely with your needs.

In this article, we’ll share our perspective on some of the critical challenges the mass timber industry faces today. Our clear intention at CLT Toolbox is to help “grow the pie” of mass timber buildings—and we believe this growth happens when we collectively simplify processes, drive efficiency, and make solutions more cost-effective.

Solving Collective Industry Problems, Can Help Grow The Pie

The drivers toward timber buildings are clear and compelling. Timber construction is more sustainable, enhances human health through biophilic design, and benefits from a rapidly advancing industry with improving cost efficiencies.

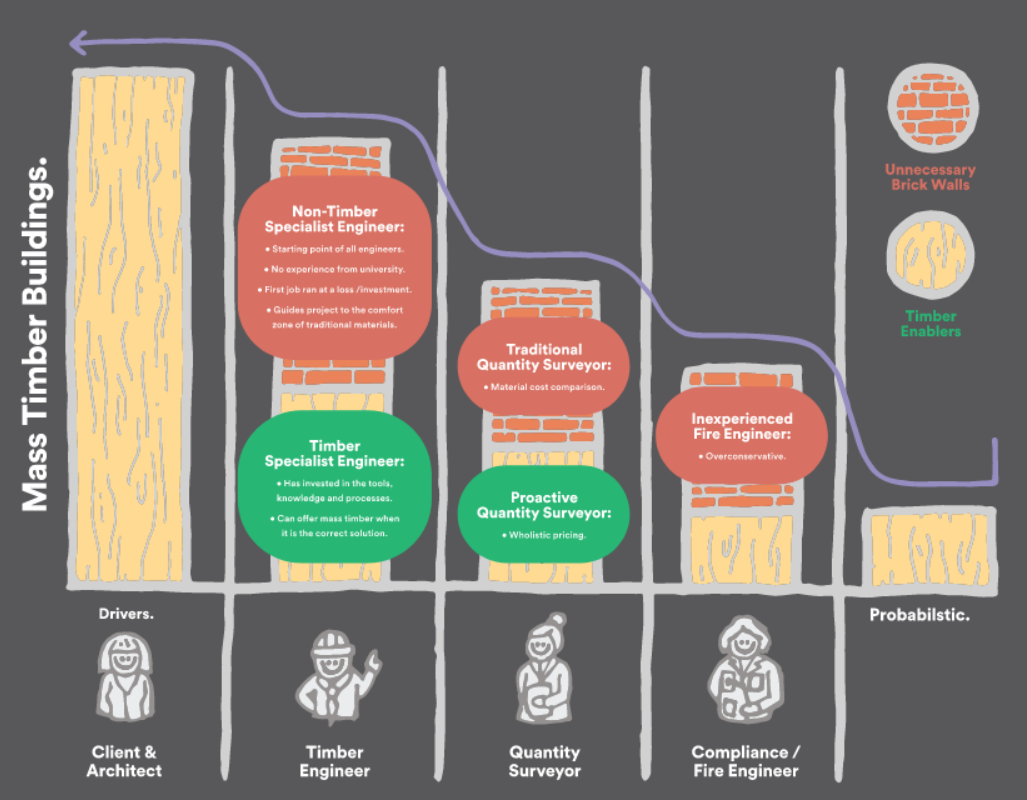

However, for many within the design community, adopting new design methods (like mass timber) and approaches presents significant challenges. Within each profession there are barriers hurdles which include accurately estimating costs for timber construction, navigating the subjectivity around fire safety design and compliance, and addressing the shortage of timber-specialist professionals.

Several solution providers are diligently working to resolve these industry bottlenecks and accelerate the growth of timber construction. Our particular focus is on structural engineers.

We believe that achieving a greater than tenfold improvement in the efficiency and ease of designing timber buildings can lead to proportional growth across the entire industry.

Solving any of these bottlenecks will dramatically improve the industry’s growth. At CLT Toolbox, we’re explicitly focusing on structural engineers. Our goal is clear: by developing productive, user-friendly tools, we aim to unlock a magnitude increase in the number of engineers capable of effectively designing mass timber buildings. Achieving this target will significantly reduce barriers, accelerate project design timelines, and ultimately drive wider adoption of mass timber construction.

So what are the problems plaguing the engineers that we’re focusing on?

Top 10 Problems We’re Helping With

Through extensive research and conversations with structural engineers and suppliers, we’ve identified three common paths in timber design:

- Status Quo

- Timber without Infrastructure (facing hurdles below)

- Timber With Our Infrastructure (elimination of hurdles)

At CLT Toolbox, we’re looking to open up the third path. This third path represents one where the following challenges are handled.

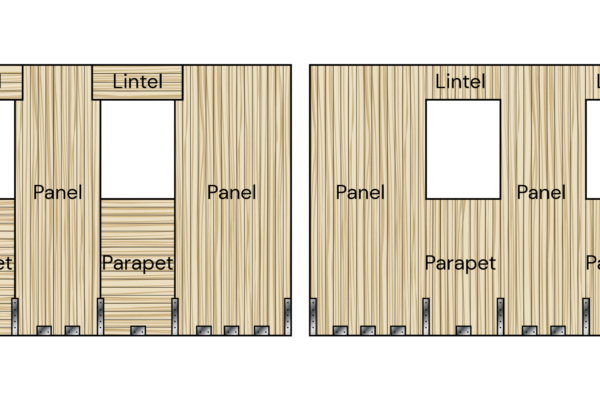

1. Managing Product Availability & Grades of the Supply Chain

Problem: Concrete and steel have standardized products and consistent, homogeneous grades. In contrast, mass timber products frequently vary in grade, specification, and availability, complicating precise and efficient selection and specification. Manually tracking these continual changes can be time-consuming and error-prone.

Solution: We engage regularly with suppliers to ensure the latest product grades, connections, and panel layups are integrated into our platform, providing real-time accuracy for your designs.

2. Education

Problem: Formal education in timber design at the undergraduate level varies significantly by region, with many engineers receiving minimal training. This forces firms to bear the cost of extensive on-the-job education (costing engineering companies).

Solution: We integrate interactive, educational dropdowns directly into our tools, enabling engineers to continuously learn as they design—transforming daily tasks into ongoing educational opportunities.

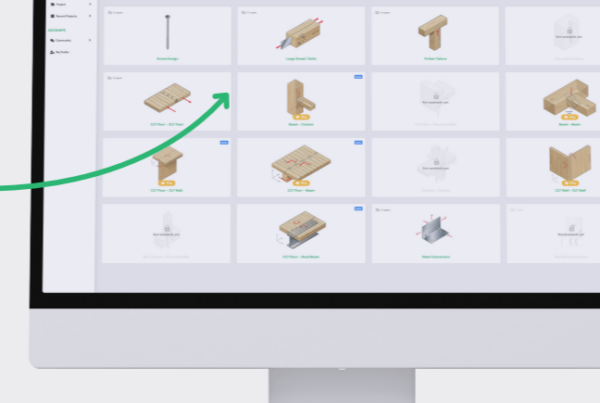

3. Building Spreadsheets

Problem: Engineers spend hundreds of unpaid hours building custom spreadsheets to perform timber design calculations, significantly increasing costs and risks.

Our research indicates that a full suite of “entry level standard tools” takes hundreds of hours. For best practice tools, it may take thousands of hours of development. In different parts of the world, there are varying levels of free infrastructure and capabilities that solve certain scenarios. Some of these include:

| Basic Member | Advanced Member | Connections | Connection Details |

| CLT Floor | Beam Penetration | Screws (Timber/Timber) | Floor/Floor |

| CLT Wall | Shear Walls | Screws (Steel/Timber) | Floor/Timber Beam |

| CLT Beam | Diaphragms | Anchors | Floor/Steel Beam |

| Timber Beam | Timber Concrete Composites | Brackets | Beam Notch |

| Timber Column | Ribbed Decks | Steel Plates | Beam/Column |

| Tension Member | Fire Design | Dowels/Bolts | Beam/Beam |

Solution: By “solving it once and turning it into infrastructure”, every engineering company doesn’t need to build the exact same tools. Currently, this results in significant repetition and waste in the design process, driving up the cost of design.

4. Maintaining Spreadsheets

Problem: Step 1, is to build all the spreadsheets. But what sometimes gets lost is maintenance! Codes change, research develops and standards update. Each change, represents a new update across excel – for every engineer in the industry.

Solution: By building a platform, maintenance costs can be solved once for the industry driving down the waste and inefficiencies.

5. Maintaining Supply Chain Flexibility

Problem: Committing to a single supplier early in the design process has benefits and a time and place. But can also limit an engineer’s flexibility and inflate project costs due to reduced competitive bidding.

Solution: Our platform enables quick and easy comparisons across multiple suppliers, ensuring you retain flexibility meaning the best supplier is available for every job.

6. De-risking Supplier Changes

Problem: Some stocked products change. This can cause problems late in projects!

Solution: Our tools allow engineers to quickly adjust designs to new suppliers or different product specifications, minimizing project disruption and financial risk.

7. Optimizing & Reducing Costs

Problem: The graveyard for most mass timber projects is the dreaded QS costing round—if timber ends up pricier than the standard approach, the status quo usually wins out.

Solution: Built-in optimization tools help engineers pinpoint cost-saving opportunities early, making mass timber designs more competitive—and more likely to actually get built.

8. Helping Certifiers Certify Buildings

Problem: Building certifiers are still figuring things out too. Sending them messy screenshots of spreadsheets and unfamiliar models makes their job even tougher. On top of that, third-party reviewers often aren’t timber specialists, so they rely on clear, professional documentation to confidently stamp approvals.

Solution: Enabling automatically generate clean, structured PDF reports, making it easy for certifiers and reviewers to understand and approve timber designs quickly and confidently.

9. Consolidating Design Checks

Problem: There’s a heap of different timber tools floating around—from PDF design guides, supplier software tools, to industry spreadsheets—and usually, each solves only one specific issue.

Our Goal: We’re bringing everything together: from member design to connection details. Our platform consolidates all these design checks into one simple spot—a genuine one-stop-shop for your timber design challenges.

10. Educating Your Entire Team

Problem: Just handing over a platform and hoping for the best usually doesn’t cut it.

Solution: We offer quarterly training sessions for enterprise clients, walking your entire team through exactly how to get the most out of our tools – to design real buildings. That means your engineers will feel confident designing timber apartments, hotels, offices, and even industrial buildings.

BONUS: Solving Infrastructure Challenges for Suppliers

Problem: Suppliers traditionally invest significant amounts of money developing individual, proprietary software solutions, creating redundant infrastructure across the industry.

Solution: We offer a shared, industry-wide infrastructure that suppliers can collectively leverage, significantly reducing redundant investments. By solving these common challenges once, all suppliers and engineers benefit from the efficiencies created.

Spot-on, Adam. I can personally attest to spending hundreds of hours developing spreadsheets (or in my case, Mathcad-style worksheets that made it a little less “black box” and easier for others reviewing my calcs). And yes, maintaining that investment becomes burdensome, especially when you don’t realize a change in the latest code cycle made one’s laborious calcs out-of-date, but you have a new project needing those calcs, so you have to stop what you’re doing to quickly update your calcs first! We also ran into Item #6 with material delays (with certain sizes of screws in particular) creating a lot of pressure to redo a lot of our calcs to accommodate substitution requests from the contractor on 3 different projects. And related to #9, quite a bit of preliminary time on our last big mass timber project was spent just searching for and painstakingly finding design resources from all over the world for some of the novel (in the US) features for that building. A “one-stop shop” would’ve been such a huge help! Keep up the good work!