What are ETAs and ICC-ESRs?

When it comes to building with timber, choosing the right fasteners is crucial for ensuring structural integrity and safety. In order for fasteners to be used in construction in a way that is compliant with structural design codes they need to be certified and evaluated. Two key players in the evaluation and certification of fasteners for timber structures are the European Technical Assessment (ETA) and the International Code Council Evaluation Service (ICC-ES). ETA provides certifications for fasteners in line with European standards, while ICC-ES evaluates fasteners for compliance with the International Building Code (IBC) and International Residential Code (IRC) in the United States. With timber construction on the rise – especially in mass timber applications – understanding the role of ETA and ICC-ES in certifying fasteners like structural screws is essential for builders, engineers, and architects.

Connection design with ETA

ETA is a European technical approval granted by the European Organisation for Technical Approvals. The ETA provides scientific and technical evidence that a product meets specific performance requirements. In order for products to display the CE mark they must be subjected to an ETA. The CE mark is required in order to sell products in Europe and shows that the product has been independently assessed and conforms to all relevant European directives.

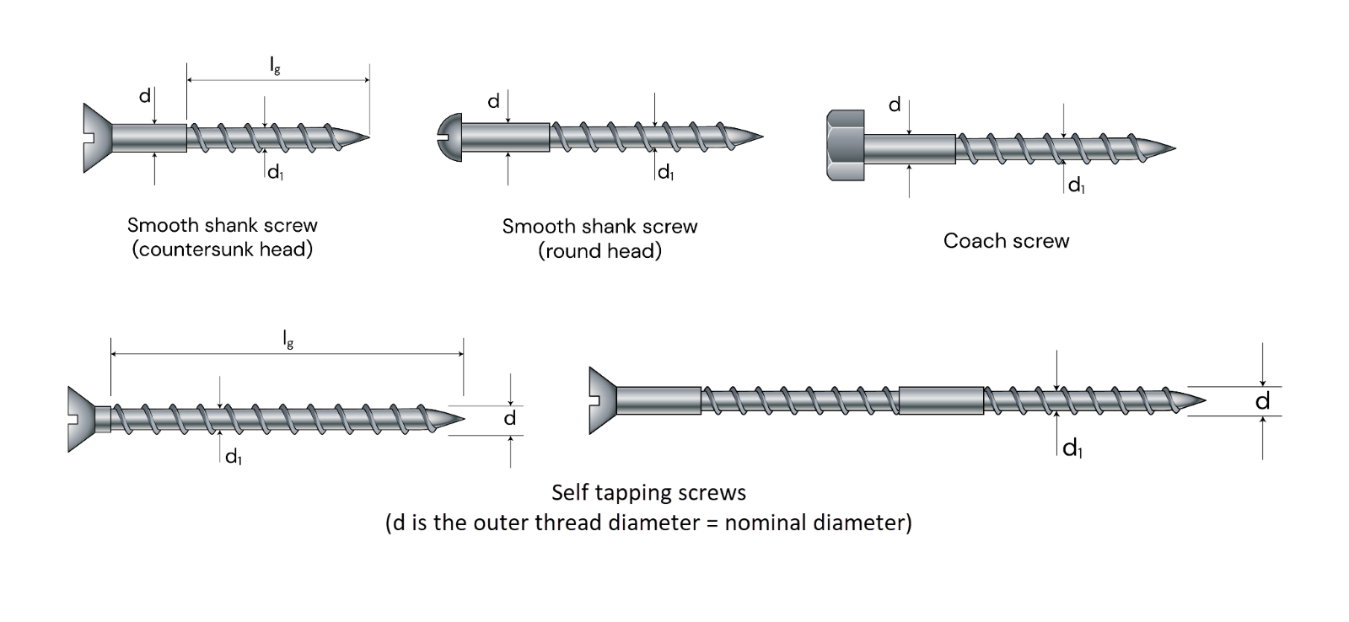

In order to be approved by the EOTA the specified fastener needs to go through rigorous testing. The results of this testing are geometric and mechanical properties (diameter, length, thread length, thread diameter, yield moment), spacing and distance requirements, and strength.

The strength values obtained by testing can be represented in the ETA by various equations needed to obtain the characteristic strength values or by tabulated characteristic strength value. In both of these cases the strengths are dependent on the application of the fastener (applicable service classes), type of timber (softwood or hardwood) and timber products (LVL, CLT, GLT, plywood), angle to the grain, etc. These criteria are usually taken into account by various modifying factors or, as is the case for embedment strength for different timber products, completely different formulas.

The value of the ETAs for the engineers is that the fastener strengths obtained through these documents supersede the strengths that can be calculated by the generic equations presented in the Eurocode. The strengths obtained through equations in the ETAs are usually of higher value than those obtained through generic Eurocode equations. Geometric requirements such as spacing and edge distances are also usually less strict in the ETAs .

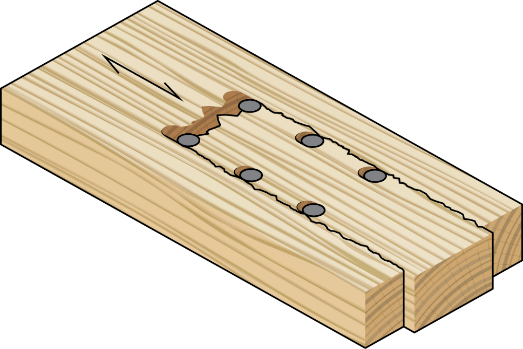

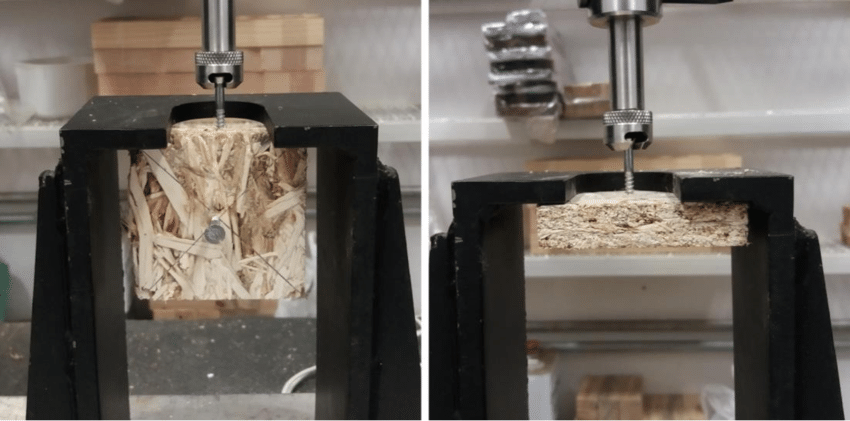

Edge and face screw resistance test

Connection design with ICC-ESR

Across the pond in the USA, approval and certification is provided by the International Code Council with its Evaluation Service (ICC-ES). As stated earlier, this evaluation service proves that the specified fasteners are compliant with International Building Code (IBC) and International Residential Code (IRC) which are governing building and construction codes in the USA. To gain approval fasteners are subject to extensive testing. The results of this testing are present in the ICC-ES Evaluation Report (ESR) and include geometric and mechanical properties (diameter, length, thread length, thread diameter, yield moment), spacing and distance requirements, and strength.

The strength is represented through tabulated reference values (withdrawal, pull-through, lateral, etc.). These tabulated values have very specific criteria that need to be satisfied in order for those values to be applicable. These criteria include embedment depth, side member thickness, specific gravity of timber members, orientation of main member (end grain, face), steel plate thickness, etc. If these criteria are not satisfied the engineer can calculate the strength using generic equations present in the NDS. Same as for strengths in the ETAs, the strength values presented in the ESR supersede the strengths obtained through NDS equations and are usually of higher value. The geometric requirements such as spacing and edge/end distances are also less strict in ESRs.

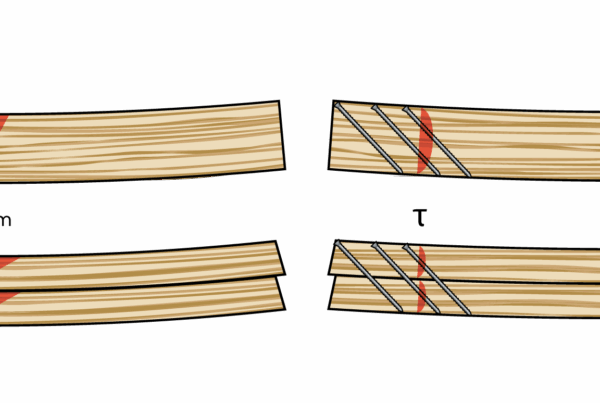

Bending test of screw

Benefits and considerations of using ETAs and ESRs for connection design

When designing timber screws, using ETAs or ESRs an offer several benefits over relying solely on structural timber design codes (EN1995-1-1, NDS):

– Product-Specific Data: ETAs and ESRs provide detailed, product-specific information on the performance of timber screws, including withdrawal, pull-through and lateral capacities. This can lead to more efficient and accurate designs compared to the more general guidelines in structural timber design codes.

– Validated Performance: ETA and ESR certification ensures that the screws have been tested and validated for specific applications, giving engineers confidence in their performance.

– Optimized Designs: By using ETA and ESR data, engineers can create more optimized designs, potentially reducing material usage and costs while maintaining safety and performance standards.

– Compliance: ETA certification demonstrates compliance with European regulatory requirements, while ESRs demonstrate compliance with International Building Code (IBC) and International Residential Code (IRC) requirements. These compliances simplify the approval process for projects.

– Access to Advanced Design Methods: ETAs and ESRs often include advanced design methods and formulas that may not be covered in Eurocode 5, allowing engineers to take advantage of the latest research and technology. For example, many screw ETAs provide formulas for using screws as shear, compression and tension reinforcement.

– Increased Design Flexibility: With product-specific data, engineers may have more flexibility in their designs, enabling them to use a wider range of screw types and configurations.

Engineers designing connections using ETA and ESR data have to be mindful of a few design considerations:

– Product Specificity: ETAs and ESRs are specific to individual products, so engineers need to ensure they are using the correct ETA or ESR for the specific screws they are designing with.

– Staying Up-to-Date: ETAs and ESRs can be updated or changed, so engineers should always verify they are working with the most current version.

CLT Toolbox can help with both

Using CLT Toolbox’s connection calculators, engineers can design connections with strength values obtained through Eurocode 5 equations or through equations present in ETAs of our fastener supplier partners. For our North American users, we are also currently working on implementing NDS and CSA connection calculation along with tested strength values present in ESRs of our North American fastener supplier partners.