Timber failures can be a critical concern in mass timber connection. In the field of mass timber construction, the complicated nature of forces within timber connections presents a complex challenge for structural engineers and architects. The reliability and performance of these connections are of paramount importance, and understanding the failure modes is crucial. In this blog, we’ll delve into the various technical aspects of timber connection types used in mass timber buildings. These connection types include post and beam connection of GLTs, connections in cases where CLT panels are supported by GLT columns or when CLT panels support GLT columns, connections in lateral bracings, and connections in notched members. We further explore the potential failure modes associated with these connections, such as bearing failures; compression perpendicular to grain in CLT and GLT, tension failure, and shear failure. Understanding these failure modes is essential for ensuring the safety and durability of mass timber structures. CLT toolbox has now incorporated these connection types and provides a comprehensive checking tool for the various possible timber failure modes resulting from such connections. Also, discover how CLT Toolbox, a cutting-edge software solution, can revolutionize the way we address these challenges.

Common Timber Connection Types in Mass Timber Buildings

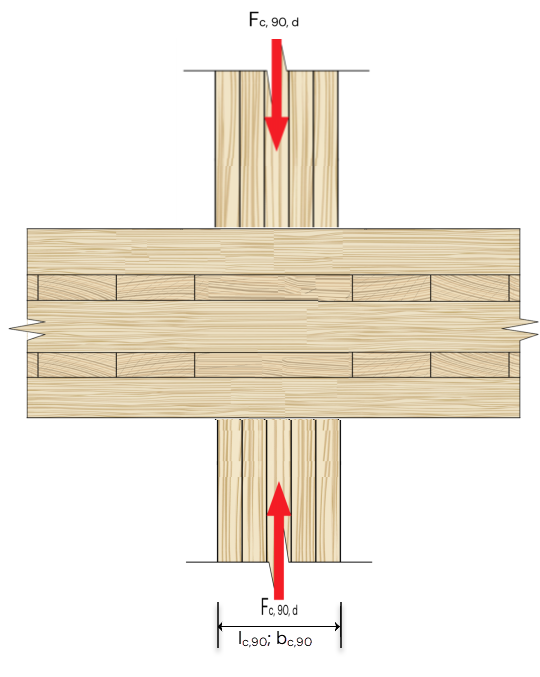

Compression Perpendicular to grain in CLT: One of the most prevalent types of timber connection in mass timber buildings occurs when CLT panels are supported by GLT columns or when the CLT panels support a GLT column, which is typically apparent in flat panels. Such type of connections result compression perpendicular to grain in Cross-Laminated Timber (CLT) panels, which requiring a particular attention. The CLT panels in these cases are subjected to a compressive force perpendicular to grain on either the top or bottom sides of the CLT member. This type of loading may result in the bearing failure of the CLT members, thus, should be checked for tensile and compressive stresses. An illustrative figure on the loading of such CLT member is shown below.

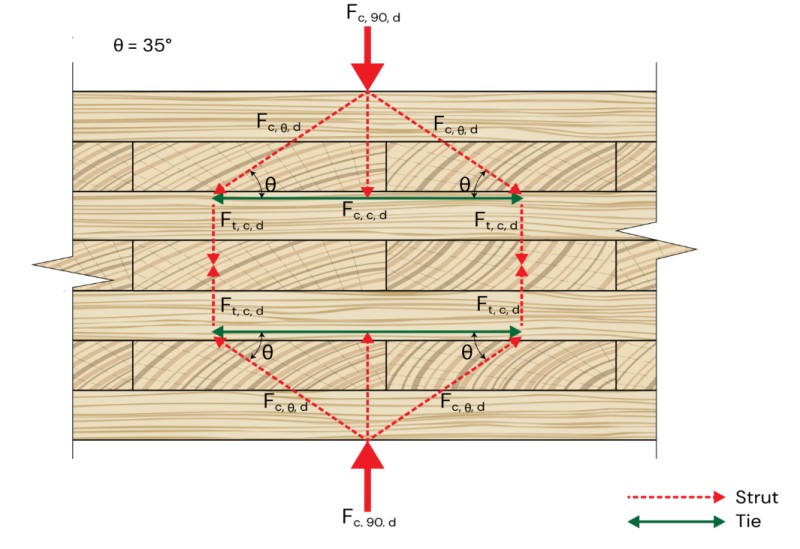

The load distribution due to the compressive force applied perpendicular to the grain is calculated using the strut and tie approach which provides a clear and effective means to calculate stress distribution in timber structures. The strut and tie model is a simplified analysis method used in structural engineering to represent complex stress paths as linear struts (compression) and ties (tension). In such cases, this approach helps in visualizing and calculating how the compressive force spreads within the timber elements. The angle used for the calculation of the load distribution for this approach, θ=35o, is taken from prEN 1995.1.1:2023, which suggests a stress spreading gradient of 35o for CLT. The choice of a 35o angle for stress spreading in CLT, is based on extensive research and testing. This angle reflects a balance between structural efficiency and safety, ensuring that the stress distribution is accurately represented for optimal structural design as suggested by the code.

CLT Toolbox can simulate these stress distributions using the strut and tie model, allowing designers to visualize and adjust their designs accordingly. By integrating prEN 1995.1.1:2023 and AS1720.1 guidelines into the design software, it ensures adherence to the latest standards and best practices.

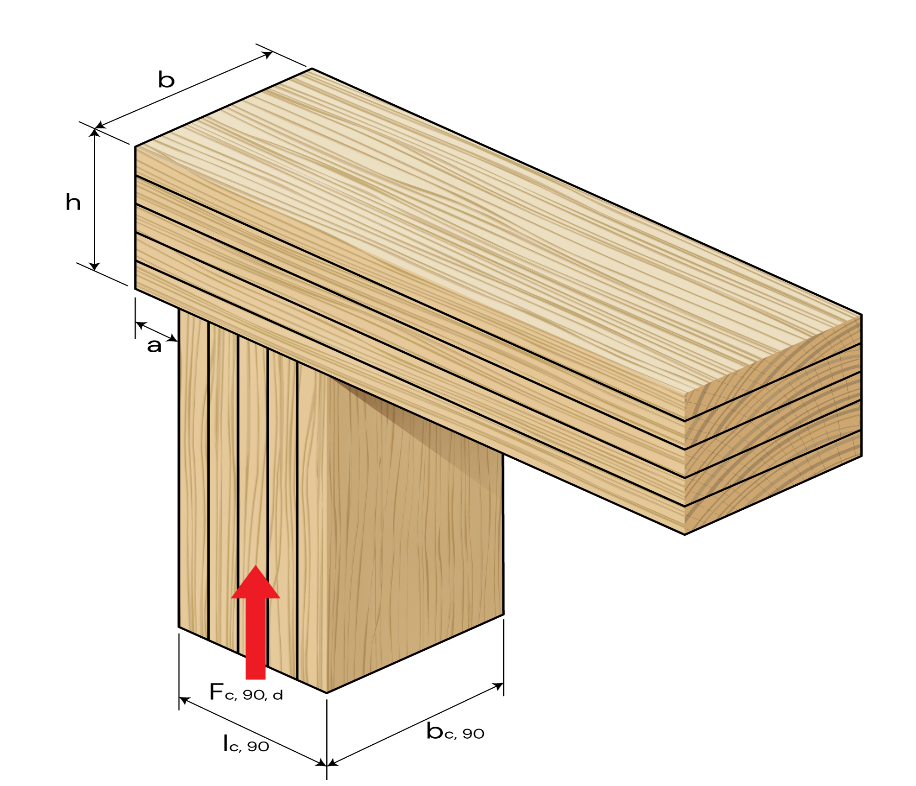

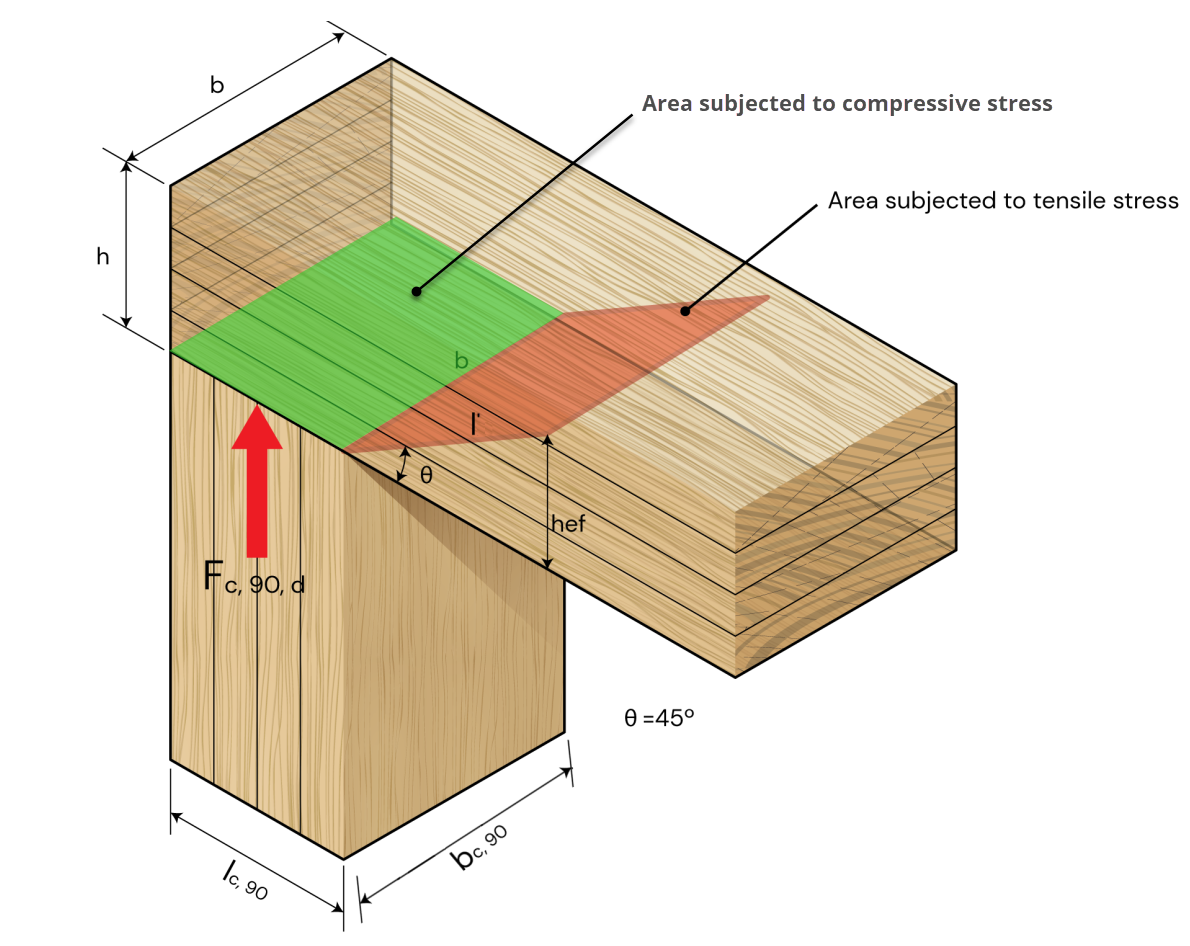

Compression Perpendicular to grain in GLT: The other common type of connection is when GLTs are subjected to a compressive force perpendicular to grain as can be seen below. The application of such type of connections can be observed when a GLT beam is supported by a GLT column. This type of loading may result in the bearing failure of the GLT members, thus, should be checked for tensile and compressive stresses.

The stress distribution technique uses more or less the same approach as discussed earlier. The only difference lies in the gradient used for GLT members. The latest Eurocode, prEN 1995.1.1:2023, recommends a stress distribution gradient of 45o for GLT members when a compressive force perpendicular to grain is applied.

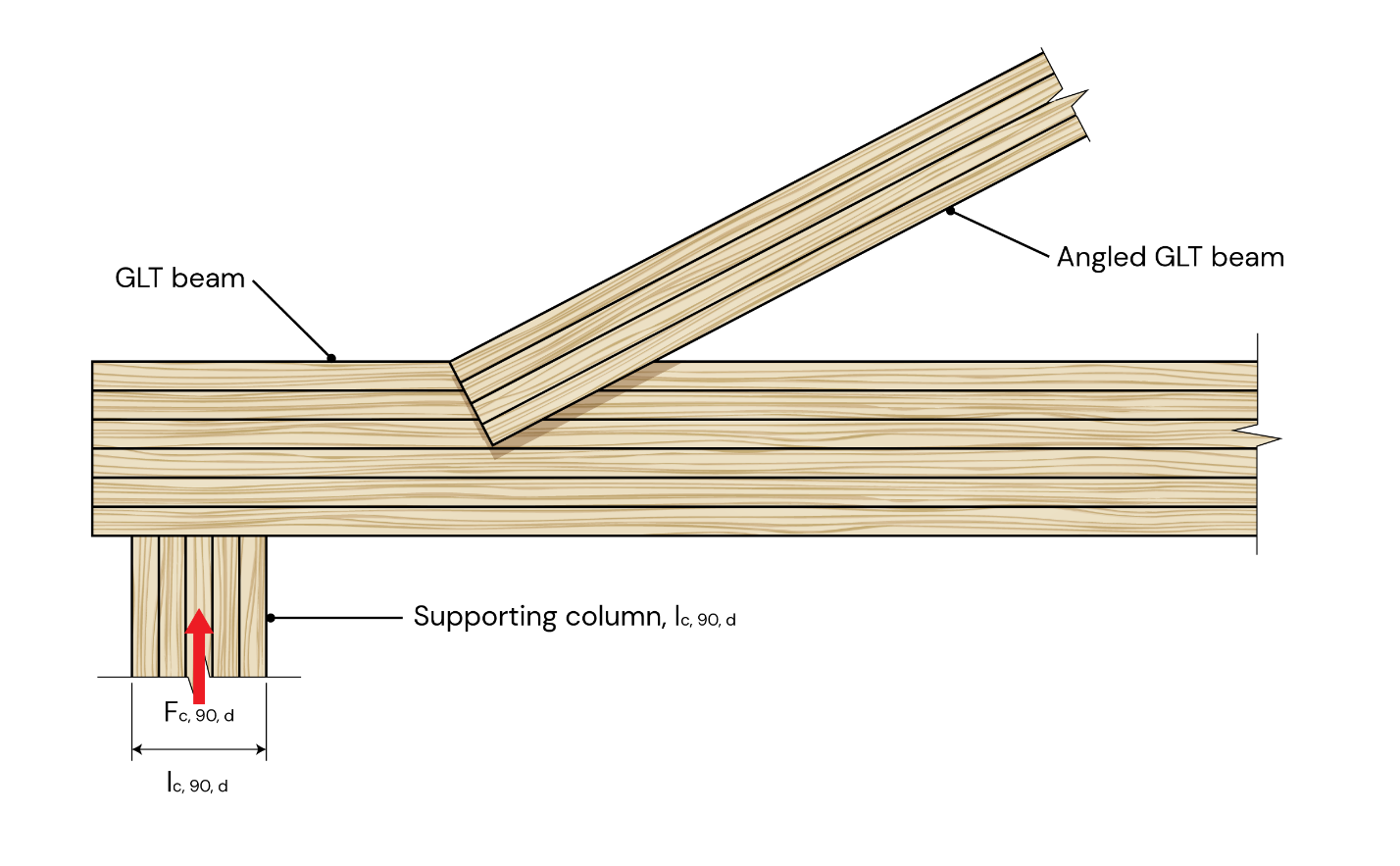

Force at an angle: In the lateral bracings of mass timber buildings, angled forces often come into play. When a force is applied at an angle, it introduces both vertical and horizontal force components on the primary (horizontal) member. This complexity requires a detailed understanding of angled forces and how they impact structural elements. This type of forces are usually found in the lateral bracings of mass timber buildings, and it can either be tensile or compressive force in nature. The distribution of loads changes with angled forces, potentially leading to uneven stress distribution and localized points of weakness. Angled forces can cause tension and compression stresses within a structure, requiring careful analysis to ensure stability and integrity. The design of connections in structures must account for these multi-directional forces to prevent failure.

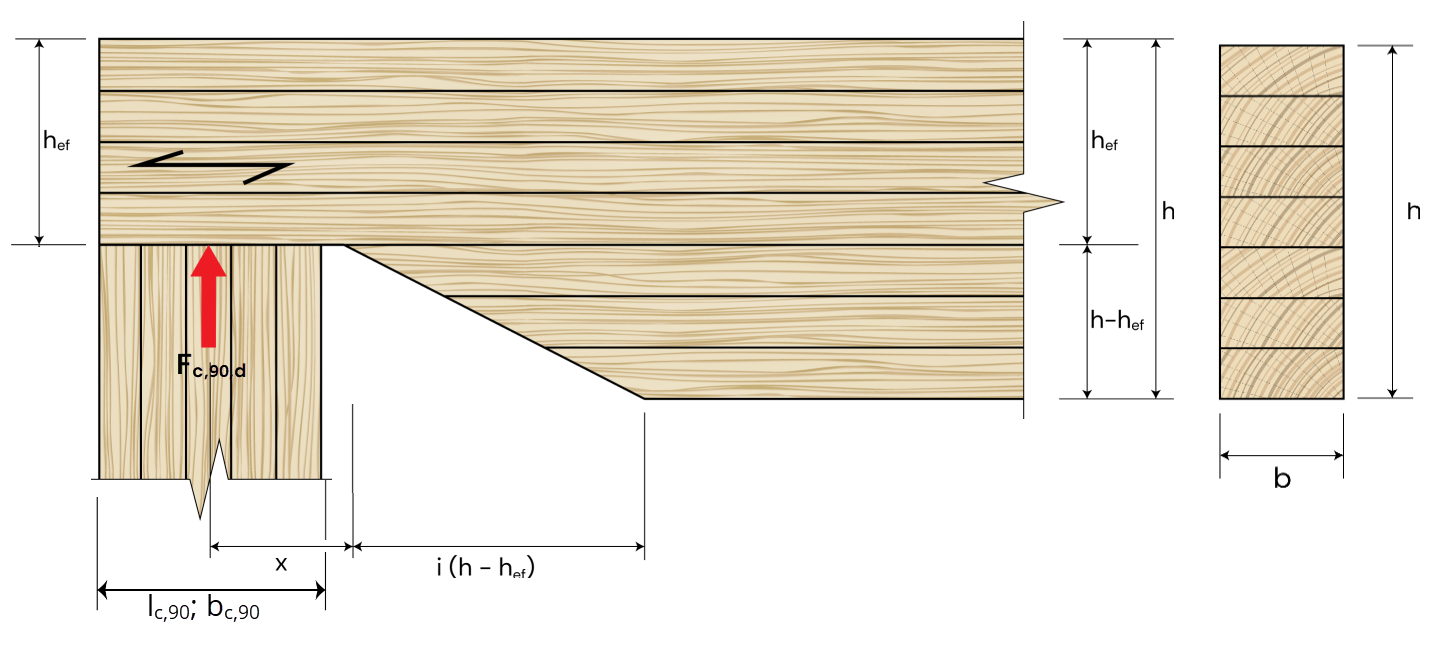

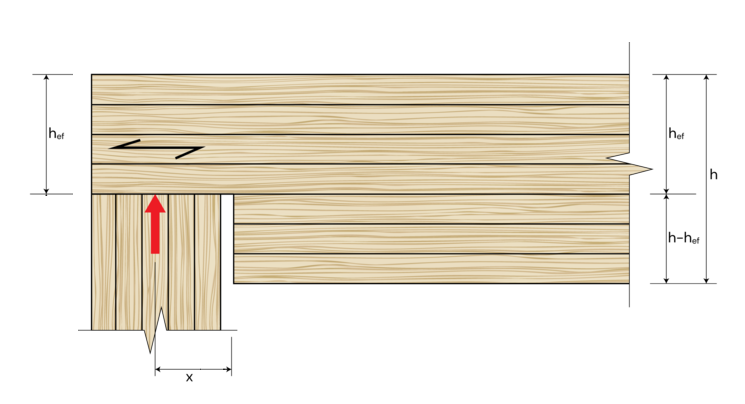

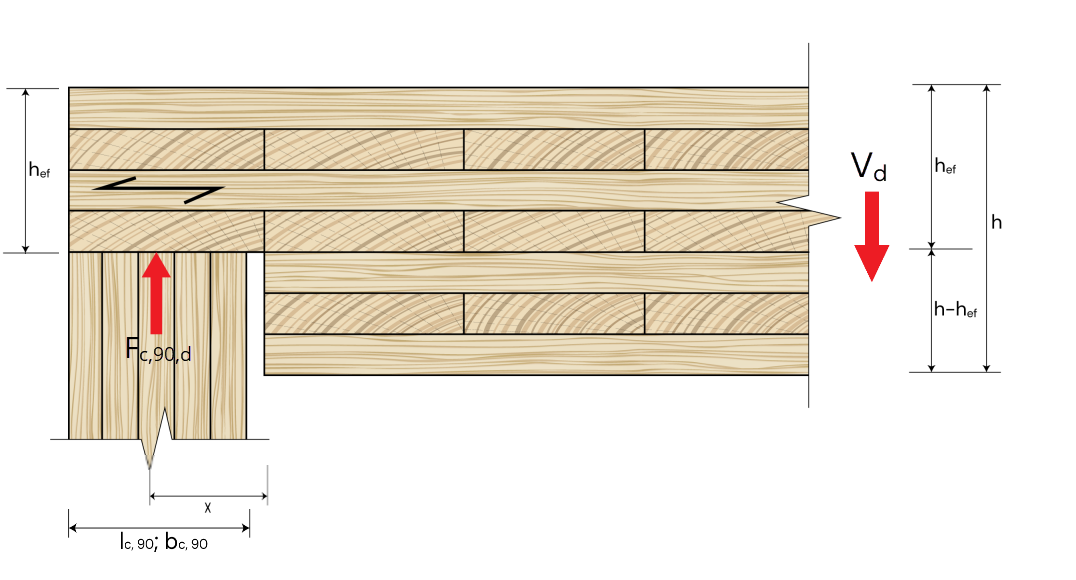

Notched Members (GLT and CLT): Notching involves removing a part of the member, typically at the ends or along the length, to facilitate connections or accommodate other structural elements. This process, however, can significantly affect the stress distribution and overall strength of the notched member. The notched member might either be GLT or CLT. Notches can create points of high stress concentration, potentially leading to cracks or failure, thus should be checked for shear, tension, and compression stresses. The geometry of notches can lead to complex load distribution patterns, making analysis and design more challenging. This is where CLT Toolbox comes into play; it integrates the complex load distribution pattern into the software calculation, simplifying and precisely accounting for the design of notched members in Mass Timber buildings. The figures below showcase an inclined and vertical notch in GLTs.

The European code, prEN1995.1.1, outlines methods to calculate the bearing capacity of notched members and offers safe and reliable design procedures for GLTs. The Australian standard, AS 1720.1, also provides comprehensive and systematic guidance on the design of notched GLT members. While both the European Code and Australian Standard offer robust design methodologies for notched GLTs, addressing notched CLTs can be more challenging. The reason lies in the limited availability of specific guidelines and standards for CLT notching. Unlike GLTs, which are used as individual members with well-defined cross-sections, CLTs are often used as panels with complex geometries and multiple connections. The design of notched CLTs remains a challenge due to the lack of specific standards. Engineers working with CLTs must exercise caution and thorough analysis when designing notched connections. As the use of CLTs continues to grow, it is essential for the industry to develop standardized guidelines to address this gap in the design process. In the meantime, precise engineering practices and collaboration among experts are vital for the successful incorporation of notched CLTs in modern timber structures.

Understanding Key Timber Failure Checks

Timber connections are fundamental in the structural integrity of timber buildings. Ensuring these connections withstand various stresses—compression, tension, and shear is crucial.

Compression Check:This check ensures if the respective connection can withstand compressive forces without buckling or crushing. The key consideration in compression checks lies in the timber’s compressive strength, which varies significantly with the grain orientation. Compression perpendicular to the grain often requires more attention due to lower strength in this direction. Compression failure arises when compressive forces exceed the connection’s ability to withstand them, causing crushing, yielding, or buckling of the timber.

Tension Check:The purpose of this check is to confirm that the connection can resist forces trying to pull it apart. The tensile strength of the timber, which varies significantly with grain orientation, is the most critical concern in tension checks. Because of its lower strength, tension perpendicular to the grain requires more attention than tension parallel to grain check. Tension failure occurs when the connection is subjected to tensile forces that surpass its resistance. This can lead to a gradual pulling apart or abrupt rupture of the timber elements.

Shear Check:This check ensures if the member can withstand shear forces without sliding, splitting, or tearing of the connected member. Shear failure occurs when the applied load exceeds the connection’s capacity to resist shear forces. It can result in sliding, tearing, or splitting of connected timber members, depending on the connection type and design.

The significance of Addressing Timber Failures in Mass Timber Connections

Timber connection failures in mass timber buildings can compromise structural safety, durability, and overall project success. Beyond safety concerns, these failures can incur substantial financial and time-related setbacks. Proper design, precise material selection, and construction practices are crucial to mitigate these risks.

How CLT Toolbox Can Help With Timber Connection Design

CLT Toolbox offers a suite of tools and resources designed to address timber connection challenges in mass timber construction. With advanced analysis capabilities and access to a library of pre-engineered connections, CLT Toolbox empowers engineers and architects to make informed decisions, optimize connection designs, and ensure the reliability of timber connections.

In this blog, we’ve delved deeper into each of these timber failure modes in mass timber connections, examining their underlying mechanisms, risk factors, and strategies for mitigation. By the end, you’ll have gained a thorough technical understanding of the complexities involved in timber connections within mass timber buildings, along with valuable insights on how CLT Toolbox can be a game-changer in addressing these challenges.

Conclusion: Elevating Timber Connection Safety

Timber failure modes in timber connections are a critical consideration in mass timber buildings. Understanding the various types of connections and their potential failure modes is essential for designing safe and durable structures. By leveraging the capabilities of CLT Toolbox, professionals can effectively mitigate these risks and contribute to the success of mass timber projects.

Incorporating strong connection designs and utilizing cutting-edge software tools like CLT Toolbox can help ensure the long-term stability and safety of mass timber buildings.

For more information on timber connection analysis and design using CLT Toolbox, please contact us or visit our website.